Casting Industry Trends in 2026 are being shaped by rapid advances in smart manufacturing, automation, and new material technologies. As global demand for higher precision, efficiency, and sustainability continues to grow, foundries are adopting intelligent production systems, automated processes, and advanced alloys to stay competitive. This article explores the key casting industry trends in 2026 and explains how these innovations are transforming steel casting quality, production efficiency, and long-term manufacturing strategies.

Table of Contents

1. Overview of Casting Industry Trends in 2026

Casting Industry Trends in 2026 reflect a major shift toward smarter, more efficient, and more sustainable production models across the global foundry sector.According to industry insights published by Foundry-Planet, global foundries are accelerating digital transformation and sustainability initiatives. Rising quality requirements, labor shortages, and cost pressures are pushing casting manufacturers to rethink traditional processes and adopt advanced technologies. Understanding these casting industry trends in 2026 is essential for both manufacturers and buyers who want to stay competitive in an increasingly demanding market.about Hanhai Casting, a professional steel and iron casting manufacturer

2.Why Smart Manufacturing Is Reshaping the Casting Industry

One of the most important Casting Industry Trends in 2026 is the rapid adoption of smart manufacturing systems. By integrating sensors, real-time data monitoring, and intelligent production planning, foundries can significantly improve process control and product consistency.our precision steel casting products Smart manufacturing not only reduces defects and downtime but also enables casting manufacturers to respond faster to customer requirements in line with casting industry trends in 2026.Industry trend analysis from Jones & Wilkinson highlights smart manufacturing as a key driver of casting industry modernization.

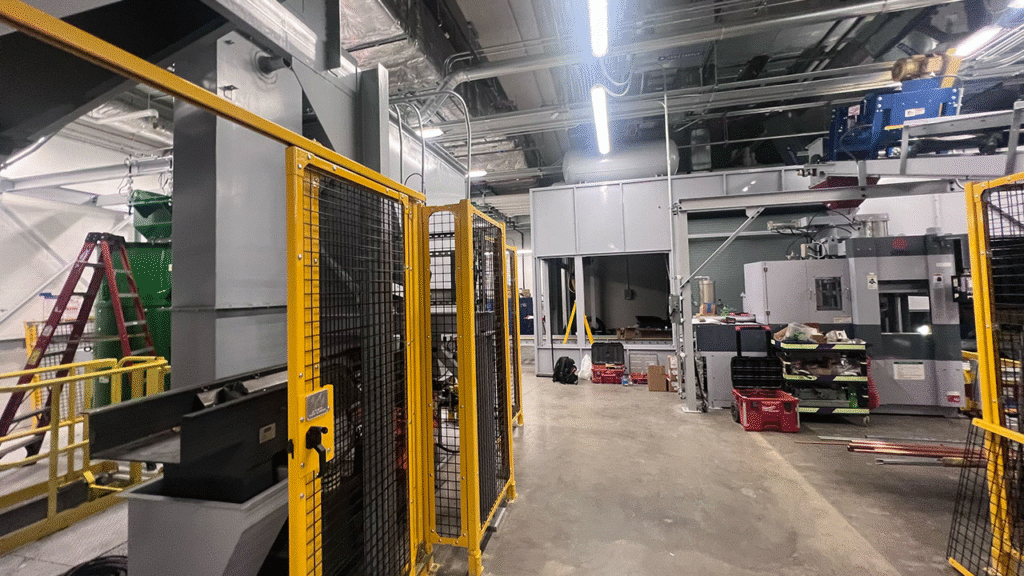

3.The Role of Automation in Improving Casting Efficiency and Quality

Automation plays a central role in Casting Industry Trends in 2026, especially in improving production efficiency and quality stability. Automated molding lines, robotic pouring systems, and CNC machining centers help reduce human error while increasing output consistency. As part of casting industry trends in 2026, automation also addresses labor challenges and enhances workplace safety in modern foundries.

4.New Materials Driving Innovation in Steel Casting

The development of advanced alloys and high-performance steels is another key aspect of Casting Industry Trends in 2026. New materials are designed to offer better strength, wear resistance, and corrosion performance for demanding industrial applications.Metallurgy experts featured on Foundry-Planet emphasize the growing importance of advanced alloys and high-performance steels. By focusing on material innovation, casting manufacturers can meet evolving customer expectations and align their product offerings with casting industry trends in 2026.

5.Digital Technologies Transforming Foundry Operations

Digital transformation is at the core of Casting Industry Trends in 2026, with technologies such as simulation software, digital twins, and data analytics becoming standard tools in foundry operations. These digital solutions allow manufacturers to optimize mold design, predict defects, and shorten development cycles. As casting industry trends in 2026 continue to evolve, digital technologies will play an increasingly critical role in decision-making and process optimization.our digital foundry capabilities and casting services

6.Sustainability and Energy Efficiency Trends in Casting

Sustainability is no longer optional and has become a defining factor in Casting Industry Trends in 2026. Foundries are investing in energy-efficient furnaces, cleaner melting technologies, and recycling systems to reduce environmental impact. These sustainability-driven casting industry trends in 2026 not only help manufacturers meet regulatory requirements but also improve their brand image and appeal to environmentally conscious buyers.

7.Challenges Foundries Face When Adopting New Technologies

Despite the benefits, Casting Industry Trends in 2026 also highlight several challenges faced by foundries when adopting new technologies. High initial investment costs, integration complexity, and the need for skilled personnel can slow down digital and automation upgrades. Recognizing these challenges within casting industry trends in 2026 helps manufacturers plan more realistic and effective transformation strategies.

Conclusion

Casting Industry Trends in 2026 highlight a clear shift toward smart manufacturing, automation, and advanced materials. These developments are reshaping steel casting quality, efficiency, and competitiveness across the global foundry industry. For manufacturers and buyers alike, understanding and adapting to casting industry trends in 2026 is essential for long-term success in a rapidly evolving market.

If you are looking for a steel casting manufacturer aligned with the latest casting industry trends in 2026, feel free to contact our team for technical support and customized solutions.CONTACT US